CNC in the (Model Engineers’) Workshop

Part 2

The second instalment of CNC In The (Model Engineers’) Workshop was published in the July 2013 issue of Model Engineers’ Workshop, arriving at UK subscribers on 3rd June 2013.

Part 2 featured CAM software, and some of the component parts of a typical CNC bench mill.

MEW Issue 204 : July 2013

Power supplies

I am not an electrical engineer, so I can’t claim my own power supply is in any way “approved” by any of the relevant standards institutes or safety agencies. That’s why can’t share it with you.

Commercial suppliers are either industrial manufacturers, whose supplies tend to be expensive, or the very few sources supplying to home workshop users. There is clearly a problem here, and it is to do with liability in various forms. Although the home workshop user tends to use CNC mainly for machining, commercial applications go much wider than this, with CNC now being used to control motion of a very wide range of devices. Some of these are sited in installations operating where the public are involved, or in situations where systems are providing life support. There would clearly be a problem if a power supply failed in any of those situations, and the CNC system then threatened public safety, or was unable to sustain life. For many smaller suppliers, those risks would be unacceptable.

So what are the solutions?

That rather depends on the voltage and current required from the power supply unit (or PSU, for short).

Data sheets available from suppliers of stepper motors indicate the voltages and currents required to drive their steppers. There are two types of stepper motors: unipolar and bipolar. The difference is related to the way the windings are connected, and that in turn affects the way the motors are connected, as well as the power (voltage and current) required to operate the steppers. Wikipedia has a brief description of the differences, here. Nowadays, I believe the most commonly used type of stepper is the bipolar, largely because this produces more power from a given size of motor.

Model Engineers’ Workshop dated February 1999 gives some details of Peter Rawlinson’s approach, and the February 2000 issue deals with the uniploar/bipolar choices available at that time.

Today’s approach is normally based on the use of bipolar motors and associated control electronics which are supplied in small boxes requiring only connections to steppers, PSU and control signals (see Part 1 of the series).

Taking the Gecko drive electronics as fairly typical, the PSU must supply between 24 and 80volts, depending on the stepper. There are some good design notes on the Geckodrive website, here. See section 6 especially. Using those notes, I was able to determine that I required a PSU supplying up to 80 volts.

eHow also have a set of simple steps for calculating power supply requirements, here.

Arc Euro Trade Ltd also supply details of a PSU you can build yourself, here.

Keling Inc have some supplies for sale, here.

CNC4YOU have a 36 volt supply for sale, here.

I see lots of PSUs for steppers advertised on eBay, but I cannot recommend any of them, because I have been reading comments about the remarkably short life reported by some users. You are on your own, with these. Caveat emptor and all that.

The picture at the top of this column shows the cooling arrangement for the heatsinks and motor controllers mentioned in Part 2 of the series. The fans are sited at the rear and blow air directly onto the fins of the heatsinks. Each heatsink has a set of thin shields closing the gaps between the sides of the heatsink and the back of the cabinet. These force the air upwards, along the fins, and out at the top (which vents directly to the outside. The lid of the cabinet has cutouts above these airways. Works for me.

Rotary table adapters.

Photo 15 on page 12 of the July MEW (No. 204) shows my fourth axis which is based on one of the popular rotary tables. It has been fitted with an adapter from a No. 2 Morse taper to a Boxford chuck thread, and I tapped the end and fitted it with a cap screw and large washer to keep the adapter pulled tight into the hole in the table. These adapters are commonly available in the UK. However; there appears to be a fault in this one, which I am finding it difficult to identify. The problem is that it introduces a slight eccentricity. I am using a Burnerd Griptru chuck which is adjustable for concentricity, and is adjusted true on my lathe spindle nose. If I turn a component on the lathe, then transfer the whole chuck-and-workpiece assembly to the rotary table, there is a measurable eccentricity. The table hole clocks true. The register ring on the adapter clocks true, but although the register ring should locate and align the chuck, I suspect the CNC machined thread on the adapter. I’ve had it for too long to return it to the supplier, but will probably have to make one of my own, shortly, and throw this commercial one away (assuming my own allows the chuck to rotate concentrically).

One other thing I notice about this adapter, as with all the MT2 accessories from this supplier: the tapered shaft sits well out of the top of the tapered hole. I see this on the accessories I use on the lathe, too. It’s not a major problem, but the further away from the table the chuck sits, the more vibration and the less rigidity in the setup.

Die-cast boxes.

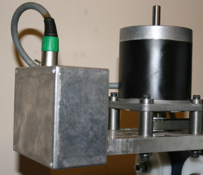

The die-cast boxes used to house the connection strips connecting the signal/power cable to the stepper winding cables is an Eddystone 26908 which measures 95 x 120 and is 57mm deep (53mm without the lid, which is the way the manufacturer specifies the size). These are made by Hammond Manufacturing, and I bought mine from RS Components, some time ago. They are currently listed as item 343-9912 at £7.41 + VAT + P&P.

The box shown in the photo holds the connections for the Z axis.

RS used to list a nice range of coated die0cast boxes, which were actually cheaper than the non-coated range. Those seem to have disappeared. I dare say that, aesthetically, there’s not much wrong with a trend bare-industrial look on a CNC machine, although we might argue over that, particularly if you have seen the stylish creation here.

There is a decent amount of space in these die-cast boxes, without them being too large. In fact, as with many things, this was not a tightly specified design decision because I had some of these left over from a previous project, and they suited this application just fine.

The manufacturer claims these boxes can be machined quite easily. I would go further and say they machine beautifully. Watch out for the pronounced taper on the sides, though. I held mine on a small tilting table, with the side to be machined held horizontally. It would be easy enough to sit the box on its end, with a small strip of material under the “heel” of the end face, to bring the top surface level. I can’t recommend the tilting table. It was so roughly made I sent it back to the supplier (who, to his credit, provided an immediate refund). The holes were CNC machined (work that one out: lashing up the connections to allow the box to be machined, and then mounting the box and making the permanent connections). Use a connector strip rated for at least 15Amps, not just for the current carrying capability, but to allow enough of a hole in each terminal to connect more than one cable simultaneously.

Importing into the UK from the USA.

Be aware that if you buy anything from the USA valued at more than £15 (or more than £36 in the case of gifts between private individuals), you will be charged import VAT by the UK Border Force on behalf of HM Revenue & Customs. The fee is collected by the carrier, which was Parcelforce Worldwide, in the case of my last purchase. Note that this applies to internet purchases as well as any of the other ways of buying goods.

There were two amounts to pay, on my latest purchase:

-

(1)import VAT of £59.49. On a purchase of goods valued at approximately £307.91 that amounts to roughly 20%, so its in line with normal VAT.

-

(2)a “Clearance Fee” of £13.50 charged by Parcelforce because they are collecting the payment for UKBF. I presume they will charge the same amount if you buy something valued at £15.01, making it a whacking fee in relation to the purchase price.

Download the article here