CNC in the (Model Engineers’) Workshop

Part 19

Instalment 19 of CNC In The (Model Engineers’) Workshop was published in the January 2016 issue of Model Engineers’ Workshop (issue 237),

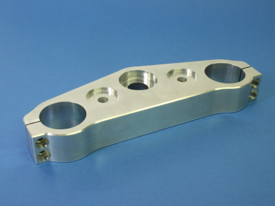

This month saw the first of two parts dealing with the manufacture of a custom top yoke for the forks of a custom Harley Davidson motorcycle.

This instalment contained information about the project, the design, tooling and workholding issues.

MEW Issue 237 : January 2016

The sub-table

It’s been mentioned before, but the little sub-table shown on page 59 of MEW 237 is just such a great addition to the mill. In fact it is almost a permanent fixture. Not only can work be clamped quickly to it, but the vice sits on a location plate (shown in earlier Parts of the series) and can be dropped onto the plate, aligned and tightened in position in 30 seconds or so. The whole arrangement is very, very handy. It’s just that I find I could always use extra holes....

One of these days, when there’s nothing much happening (!) I might get around to drilling some extra rows of holes.

The article in this month’s issue is largely self-explanatory (I hope), and most of the meat for this project can be accessed via the page for MEW 238 (Part 20).

Article not yet available for download