CNC in the (Model Engineers’) Workshop

Part 12

Instalment 12 of CNC In The (Model Engineers’) Workshop was published in the April 2014 issue of Model Engineers’ Workshop.

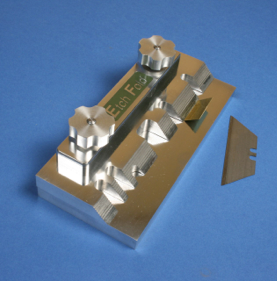

This month saw the beginning of a short project to make an Etch Folder.

While the folder itself is a useful tool, the project provides a vehicle for an explanation of a number of practical skills, both physical and software-based.

The physical skills include mounting and work holding as well as cutters for aluminium and using a countersink to form an angled face.

There is information about paths, straight lines and circles, and the software skills include some arithmetic as well.

MEW Issue 214 : April 2014

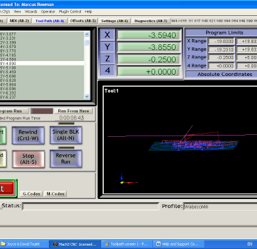

This instalment contained information about paths, straight lines and circles, and the use of Exact Stop and Constant velocity modes.

I do find the Toolpath window of considerable use in previewing the tool path, although it doesn’t give much of an indication of the effects of G61 or G64, it does give enough information that, if you look closely and note what the heights and the colours are telling you, it can indicate potential problem areas. With practice, it becomes much more likely that you will be abel to spot potential problems before you run a program. Although it is not usually of much consolation, it can explain (afterwards) why the machine did something unexpected during machining. There are always lessons to be learnt.

The little Etch Folder does illustrate some of the common problems of workholding, particularly those which inevitably occur when trying to machine all around the periphery of an object.

Much later, when we look at CAM software, we will see that there is at least one commonly used technique in which the machining path is altered to leave small “tabs” at designated positions on the periphery, so that the workpiece remains attached to the parent material but can easily be separated afterwards. That ca be a useful technique, but, to be honest, I often prefer to find a clamping solution so that I don’t have to clean up the remains of the tabs afterwards. In the case of the Etch Folder, the parts are a decent thickness, and the finish which can be obtained with a good end mill is very fine, so that cleaning up tabs would spoil the finish.

If you are prepared to accept the need for specific workholding arrangements to suit your particular workpiece, you can save work at the end.

Download the article here